In the fast-paced realm of industrial operations, optimizing floor space is paramount for enhancing productivity and efficiency. Here’s how to achieve space efficiency effectively:

- Strategic Layout Planning: Designing a layout that minimizes wasted space while ensuring smooth workflow and accessibility.

- Vertical Storage Solutions: Utilizing shelves, racks, and mezzanines to capitalize on vertical space, reducing the footprint of storage areas.

- Compact Equipment Selection: Opting for machinery and equipment with smaller footprints without compromising performance.

- Modular Workstations: Implementing modular workstations that can be easily reconfigured to adapt to changing needs, maximizing space utilization.

- Automation and Robotics: Introducing automated systems and robotics to streamline processes and reduce the need for large manual work areas.

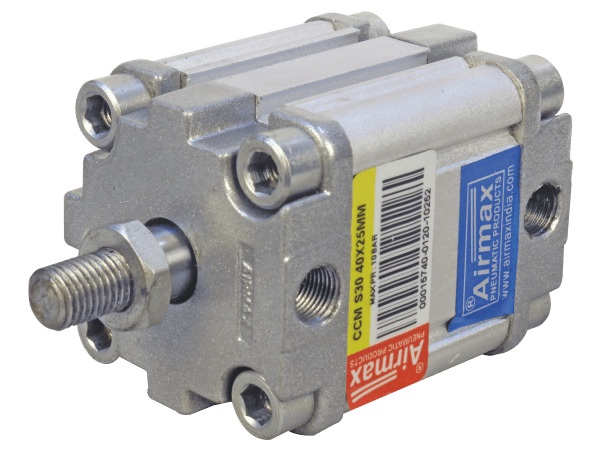

- Investing in High-Quality Compact Pneumatic Solutions: Utilizing advanced pneumatic components like the High-Quality Compact Pneumatic Cylinder in Gujarat, which offer superior performance in a compact design, saving valuable floor space.

By incorporating these strategies, industrial facilities can unlock their full potential, achieving higher efficiency and productivity within the confines of their existing footprint.

Lightweight Design: Ease of Installation and Handling

Lightweight design is a game-changer in the world of pneumatics. By opting for high-quality compact pneumatic cylinders, you can experience numerous benefits, especially during installation and handling:

- Reduced Physical Strain: Lighter weight makes lifting, maneuvering, and positioning the cylinder a breeze, minimizing worker fatigue and potential injury.

- Simplified Installation: The ease of handling allows for faster and more efficient installation, saving you valuable time and labor costs.

- Enhanced Accessibility: Compact and lightweight cylinders can be easily installed in tight spaces or on complex machinery, offering greater design flexibility.

- Improved Safety: Reduced weight lowers the risk of dropped or mishandled cylinders, promoting a safer work environment.

In Gujarat, for all your pneumatic needs, consider high-quality compact pneumatic cylinders. Their lightweight design, coupled with exceptional performance, ensures a smooth and efficient installation process for your projects.

High Force-to-Size Ratio: Achieving Powerful Performance in Compact Packages

Imagine packing a powerful punch in a tiny package. That's the magic of high force-to-size ratio technology. It allows engineers to design compact actuators that deliver impressive force outputs. This translates to several benefits:

- Space Efficiency: Smaller actuators free up valuable space in machines and devices, leading to more compact designs.

- Lightweight Construction: Reduced size often translates to lower weight, ideal for applications where portability is key.

- Fast Operation: Smaller actuators can achieve higher acceleration and faster cycle times due to their lower mass.

- These advantages make high force-to-size ratio actuators perfect for various applications, from robotics and automation to medical devices and aerospace.

Look no further! Airmax Pneumatic offers a range of high force-to-size ratio pneumatic cylinders designed for exceptional performance in compact spaces. Contact us today to discuss your specific needs.

Quick Response Time: Enhancing Production Speed and Efficiency

In today's fast-paced manufacturing landscape, achieving optimal production speed and efficiency is paramount. A key factor in accomplishing this goal is ensuring quick response time throughout the production process. Here's how enhancing response time can significantly boost productivity:

- Reduced Downtime: Quick response times minimize downtime, ensuring that equipment and machinery are operational more frequently.

- Streamlined Processes: Efficient response times streamline workflows, allowing for smoother transitions between tasks and operations.

- Improved Customer Satisfaction: Rapid response to customer inquiries and orders leads to higher satisfaction rates and repeat business.

- Enhanced Safety: Fast response times can mitigate potential safety hazards by promptly addressing issues and preventing accidents.

- Integration of High-Quality Components: Incorporating high-quality components like the High-Quality Compact Pneumatic Cylinder in Gujarat ensures reliability and durability, further optimizing production processes.

By prioritizing quick response times, businesses can not only accelerate production but also maintain a competitive edge in the market.

Cost-Effectiveness: Lowering Initial Investment and Operational Expenses

When starting or running a business, keeping costs down is crucial. But that shouldn't mean sacrificing quality. Here's how to achieve both:

- Lower Initial Investment: Consider high-quality, compact pneumatic cylinders. These offer the functionality you need without the bulk, often leading to lower upfront costs compared to larger models.

- Reduced Operational Expenses: Compact cylinders typically require less energy to operate due to their size and design. This translates to long-term savings on your energy bills.

- Minimized Maintenance Needs: High-quality cylinders are built to last, reducing the need for frequent maintenance and repairs.

- In Gujarat, for instance, you can find High-Quality Compact Pneumatic Cylinders from various reputable suppliers, ensuring both affordability and performance.

By focusing on these strategies, you can ensure your business operates cost-effectively without compromising on quality.

Versatile Applications: Adaptable Solutions for Various Industrial Processes

Modern industrial processes demand adaptability and efficiency. This is where versatile equipment comes in, offering a range of benefits:

- Reduced Complexity: Single, adaptable machines can handle multiple tasks, streamlining production lines and reducing the need for specialized equipment.

- Increased Efficiency: Quick changeovers between processes minimize downtime and keep production flowing smoothly.

- Improved Flexibility: Adaptable solutions can be easily configured to meet specific needs, allowing for adjustments as production requirements evolve.

For instance, high-quality compact pneumatic cylinders offer a perfect example of such adaptable equipment. These versatile actuators, available from leading suppliers in Gujarat like Airmax Pneumatic, can be effortlessly integrated into diverse industrial applications, from delicate assembly lines to heavy-duty material handling.

Reduced Energy Consumption: Optimizing Efficiency in Automation Systems

In today's industrial landscape, optimizing energy consumption is paramount for sustainable operations and cost-effectiveness. Achieving efficiency in automation systems not only reduces energy costs but also enhances productivity and reduces environmental impact. Here's how:

- Advanced Sensors and Controls: Implementing sensors and control systems to monitor energy usage and optimize performance in real-time.

- Energy-Efficient Components: Utilizing energy-efficient motors, drives, and components to minimize power consumption without compromising performance.

- Smart Programming: Developing intelligent algorithms and programming sequences to streamline operations and minimize energy wastage.

- Regular Maintenance and Upgrades: Conducting regular maintenance checks and upgrading outdated equipment to ensure optimal efficiency.

- Integration of Renewable Energy Sources: Incorporating renewable energy sources such as solar or wind power to supplement energy needs and reduce reliance on non-renewable resources.

When seeking efficiency solutions, consider investing in high-quality compact pneumatic cylinders in Gujarat, which can significantly contribute to energy savings and overall system performance.

Minimal Maintenance Requirements: Increasing Overall System Reliability

Systems with fewer maintenance needs experience less downtime, leading to increased productivity and cost savings. This translates to higher output for your operations.

- Enhanced Efficiency: Regular maintenance can disrupt production flow. By minimizing maintenance requirements, you streamline your processes and ensure smoother operation.

- Improved System Lifespan: Components that require less maintenance tend to last longer. This reduces the need for replacements and lowers overall ownership costs.

- Focus on Core Operations: By minimizing maintenance, your team can dedicate more time to core operations and strategic initiatives, maximizing their impact.

For instance, utilizing high quality compact pneumatic cylinders in Gujarat can significantly reduce maintenance requirements in your machinery. These cylinders are known for their durability and extended lifespans, requiring minimal intervention to keep your system running smoothly.

No comments yet