Automotive casting is a crucial manufacturing process in the automotive industry, serving as the backbone for producing various vehicle components. From engine blocks to transmission housings, automotive castings play a pivotal role in the structural integrity and functionality of vehicles. In this comprehensive guide, we will explore the various aspects of automotive casting, from design considerations to the production process.

Section 1: Types of Casting Processes Automotive casting involves various casting processes, including sand casting, die casting, investment casting, and more. Each method has its own advantages and is chosen based on the specific component's requirements.

-

Sand Casting: Sand casting is the most versatile and widely used method. It's suitable for manufacturing larger components like engine blocks and cylinder heads.

-

Die Casting: This process is ideal for producing complex, high-precision components like aluminum wheels and transmission housings.

-

Investment Casting: Investment casting is known for its ability to create intricate, detailed parts such as turbocharger impellers and exhaust manifolds.

Section 2: Design Considerations Proper design is crucial in automotive casting to ensure the final component meets performance, durability, and safety standards. Key design considerations include:

-

Material Selection: Choosing the right material, such as aluminum, iron, or steel, is essential for the component's intended function and performance requirements.

-

Casting Geometry: The design should optimize the casting process, minimize defects, and promote uniform cooling for consistent material properties.

-

Tolerances: Precise tolerances should be specified to ensure that cast components fit and function correctly within the vehicle.

Section 3: The Casting Process The casting process involves several stages, from creating a pattern to finishing the cast component:

-

Pattern Making: A pattern, often made from wood or plastic, is created to shape the mold cavity.

-

Mold Formation: The pattern is placed in a mold box, and a mold material, typically sand, is compacted around it to form a mold cavity.

-

Melting and Pouring: The chosen metal is melted in a furnace and poured into the mold cavity.

-

Solidification and Cooling: The molten metal solidifies in the mold. The cooling rate is controlled to prevent defects.

-

Casting Removal: Once cooled, the casting is removed from the mold and subjected to finishing processes like cutting, grinding, and heat treatment.

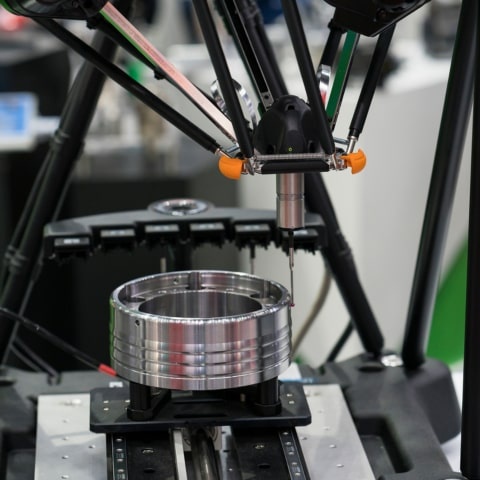

Section 4: Quality Control Quality control is vital to ensure the cast components meet industry standards. Common quality control methods include non-destructive testing (NDT), dimensional inspections, and material property testing.

-

NDT Techniques: Techniques like X-ray, ultrasonic testing, and dye penetrant inspection are used to detect hidden defects.

-

Dimensional Inspections: Components are measured to verify that they meet the specified tolerances.

Section 5: Benefits of Automotive Casting automotive casting offers several advantages:

-

Cost-Effective: Casting processes are often cost-effective for mass production due to low material waste and high repeatability.

-

Complex Shapes: Casting can produce intricate and complex shapes, reducing the need for additional machining.

-

Material Properties: Casting allows for a wide range of material options to meet specific requirements, such as strength, weight, and corrosion resistance.

Conclusion: Automotive casting is a critical manufacturing process that contributes to the production of numerous vehicle components. By understanding the different casting methods, design considerations, the casting process, and quality control measures, automotive manufacturers can create high-quality, reliable, and cost-effective components that drive the automotive industry forward. Properly designed and manufactured castings are essential for ensuring vehicle safety, performance, and longevity.

No comments yet