Business owners who want to reduce workers' compensation insurance costs need to reduce their workers' compensable injuries.

Workplace accidents often have serious consequences, not only for injured workers but also for employers. One leaves physical trauma, often requiring active rehabilitation - the other with costs incurred as a result of the incident. The saying "prevention is better than cure" certainly applies in the case of an accident at work. Fortunately, many common pitfalls can be avoided with a few simple checks. And by minimising injuries, employers can improve their claims history, lowering their rates and sometimes getting discounts from their insurance companies.

Common industrial accidents

Here are some common industrial accidents and practical tips that small business owners can use to improve their safety plans, prevent common workplace accidents, reduce risks and improve workplace safety plans.

1. Wear and tear

Given the many ways that employees can be cut or stabbed through tools, machines, tools, as well as environmental objects such as plants or animals, it is best to focus on safety precautions. General safety such as equipment maintenance, implementation and application of necessary procedures.

2. Overexertion

The most common type of overuse is back pain from heavy lifting. However, overexertion due to repetitive work can also lead to cumulative trauma disorders, such as tendinitis and carpal tunnel syndrome.

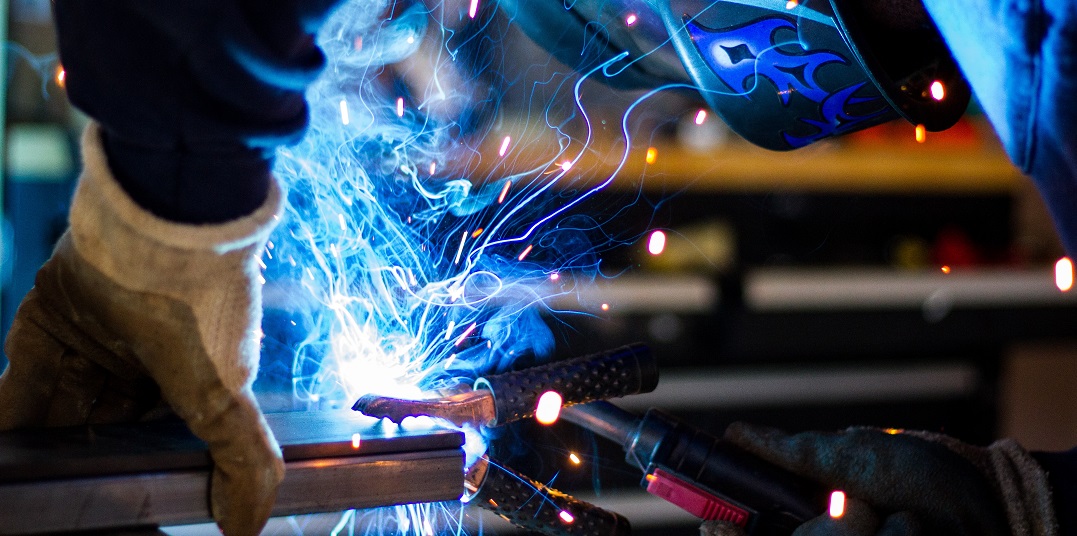

3. Fire and explosion

Fires and explosions can burn body tissues, cause severe damage to the respiratory system and potentially disfigure you. This is an uncommon work injury but has the highest casualty rate depending on your distance from the blast.

4. Falling, slipping or slipping

Certain types of floor surfaces, changes in levels and friction, and changes in floor surfaces or foreign objects can increase the risk of falling, slipping or slipping. Therefore, it is essential to have good visibility, clear obstacles and be aware of your surroundings to reduce the risk of these accidents.

5. Exposure to Hazardous Chemicals

Many products require the use of hazardous materials in the manufacturing process. This puts factory workers at significant risk of exposure to toxins. For example, chemical spills in a plant can cause severe burns, skin irritation, or breathing problems. Even when employees wear safety equipment, they are still at risk in the event of an accident. In addition, chemical accidents can cause occupational diseases. Workers exposed to hazardous materials daily are also at risk of long-term illnesses like cancer.

6. Improper use of machinery

Using the equipment at work and machinery maintenance in the workplace account for a high rate of workplace injuries and deaths. Working with heavy equipment such as forklifts and raised platforms requires specialised training to operate safely or assess the risks involved. Proper equipment training can also help certify that employees have the necessary permits before operating or maintaining machinery and build worker confidence.

Steps of Preventing Industrial Hazards

● Identify hazards in your workplace:

Hazard identification is the part of a process used to assess whether a particular situation, item, thing, etc., may be potentially harmful. For example, evaluating the work environment for health and safety risks is vital for preventing injury and illness. While there are different methods for identifying workplace hazards, these steps can be helpful.

- Conduct routine worksite inspections by visiting the worksite and visually assessing the equipment types-functionalities, operational practices, and any capacity risks that might pose industrial risks.

- Interview workers and managers, allowing them to share their concerns and experiences that might not be as evident whilst undertaking best worksite inspections. Involving workers in figuring out risks additionally will increase the workers' morale and compliance with protection practices.

- Create a hazard outline of the worksite(s) and mark present and capacity risks. Involve workers in this activity to solicit feedback and increase awareness of the importance of safety in the workplace.

- Inspect, analyse and evaluate the risk associated with that hazard to determine appropriate ways to eliminate or control the risk when the danger cannot be eliminated (risk control).

● Use the hierarchy of Controls

It would help if you always aimed to eliminate hazards from your workplace completely. When this is not practical, you should systematically investigate other alternatives. Some problems can be solved easily and immediately, while others require more effort and planning. Focusing on the most pressing hazards without ignoring hazards can be easily and instantly remedied. Some solutions are more effective than others. Make sure your solution doesn't create new threats.

Use a Decentralised Control System to eliminate or reduce risks in your workplace. It starts with the most effective method of control and ends with the least adequate (wearing personal protective equipment/PPE). You should use the highest practicable control measure to control risk. Use lower-level controls only as a last resort or until a more effective means of risk control can be used. Sometimes using multiple controls can be the most effective way to reduce exposure to hazards.

● Incorporate Industrial Safety Controls

Safety should always be a primary concern of industrial facilities, from protecting employees from accidental injury to safeguarding equipment from serious damage that could result in downtime costly to operate and repair. Industrial processes and operations use high-speed machinery, automated systems, and equipment for moving heavy parts or handling hazardous materials. Therefore, there should be safety-related features in almost every piece of equipment, industrial and non-industrial. For example, electrical appliances have enclosures protecting consumers from electrical hazards. For instance, enclosed motorised devices are intended to prevent possible injury to the user from moving parts and/or hazardous electrical parts.

In addition, industrial facilities such as flame arresters have many safety features, including safety signs that warn workers of possible hazards. All industrial safety control equipment and machines have push buttons, switches, displays, tank ventilation applications and other devices to prevent possible injury to workers and operators.

Final Words

Industrial safety is becoming increasingly important because of the millions of industrial accidents that result in fatalities, temporary or permanent disability to the workforce, along with massive loss of property, damage, and unused hours of people and machines.

Currently, much effort is made to control the frequency and intensity of accidents. Therefore, as a business owner, you should always be equipped with high-quality industrial engineering supplies and safety control devices from authentic suppliers.

No comments yet