The automotive industry has witnessed a remarkable evolution in recent years, with continuous advancements in engine components technology driving unprecedented performance and efficiency gains. From powerful race cars to eco-friendly hybrid vehicles, the engine components have become the focal point of innovation, contributing to enhanced power delivery, fuel economy, and overall reliability. Among these groundbreaking advancements, the "Studs Service Kit" has emerged as a game-changer, revolutionizing engine assembly and performance. In this article, we will explore the fueling innovation in engine components technology, with a special focus on the transformative impact of the "Studs Service Kit."

Engine Components: The Core of Automotive Power:

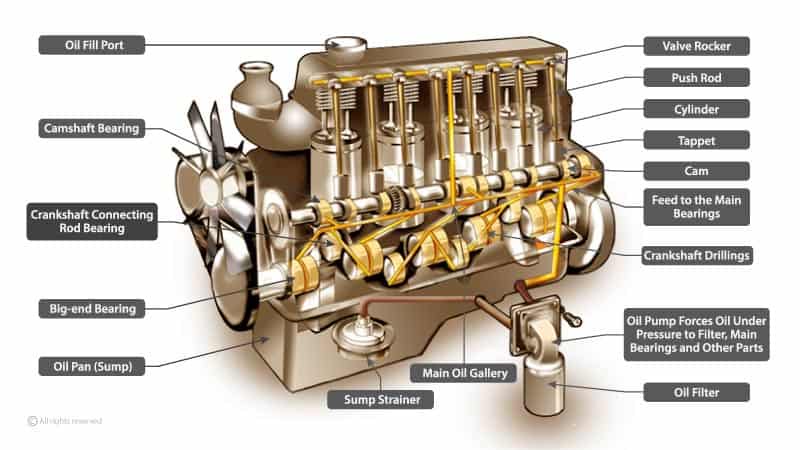

Engine components serve as the heart and soul of any vehicle, orchestrating a complex symphony of mechanical processes to convert fuel into motion. Some of the key engine components include:

-

Cylinder Head: The cylinder head houses the combustion chambers, intake and exhaust valves, and spark plugs. It plays a critical role in sealing the combustion chambers and optimizing airflow for efficient combustion.

-

Pistons and Connecting Rods: Pistons move up and down within the engine cylinders, converting the energy from combustion into mechanical motion. Connecting rods transfer this motion to the engine's crankshaft.

-

Crankshaft: The crankshaft transforms the reciprocating motion of the pistons into rotational motion, ultimately driving the vehicle's wheels.

-

Valves: Intake and exhaust valves control the flow of air and fuel into the cylinders and the expulsion of exhaust gases after combustion.

-

Fasteners: Engine fasteners, including bolts and studs, secure various components together, ensuring stability and preventing leaks.

Advancements in Engine Components Technology:

-

Materials and Manufacturing Techniques: The advent of advanced materials, such as high-strength alloys and composites, has revolutionized engine component design. These materials offer superior strength-to-weight ratios, reducing the overall engine weight and improving fuel efficiency. Additionally, innovative manufacturing techniques, such as 3D printing, have enabled complex geometries and customized components for optimal performance.

-

Precision Engineering and Design Optimization: Engine components are now meticulously designed using computer simulations and advanced engineering tools. This precision engineering ensures optimal performance, reduced friction, and enhanced durability. Components are optimized for aerodynamics, combustion efficiency, and overall system integration.

-

Smart Integration and Sensors: Modern engine components are equipped with sensors and smart integration. These sensors provide real-time data on various parameters, enabling the engine's electronic control unit (ECU) to make instantaneous adjustments for optimal performance and efficiency.

-

Thermal Management and Cooling Solutions: Innovative thermal management solutions have been employed to enhance engine cooling efficiency, reducing energy wastage and improving performance. Advanced cooling technologies, such as liquid-cooled components and variable cooling systems, have become standard features in many modern engines.

The Game-Changing "Studs Service Kit":

One of the most transformative innovations in engine components technology is the "Studs Service Kit." Developed by industry leaders, this kit offers a comprehensive package of high-quality studs and related components. The "Studs Service Kit" has been designed to revolutionize engine assembly and performance, offering several key benefits:

-

Enhanced Strength and Durability: The studs in the kit are crafted from high-strength materials, ensuring they can withstand extreme pressures and stresses. This enhances engine durability and reliability, particularly in high-performance and heavy-duty applications.

-

Perfect Fitment and Sealing: Each stud is engineered to precise specifications, guaranteeing a perfect fit and uniform load distribution. This results in a secure and stable engine assembly, preventing leaks and maximizing performance.

-

Reduced Maintenance and Downtime: With its exceptional durability and reliability, the "Studs Service Kit" significantly reduces the need for frequent maintenance and repairs, minimizing downtime and increasing productivity.

-

Optimized Performance: The "Studs Service Kit" contributes to overall engine performance by maintaining consistent clamping force, ensuring improved combustion efficiency and power delivery.

Conclusion:

Advancements in engine components technology are fueling a new era of automotive innovation. From materials and manufacturing techniques to smart integration and cooling solutions, every aspect of engine components has undergone substantial enhancements. The game-changing "Studs Service Kit" has further transformed engine assembly and performance, offering unmatched strength, durability, and reliability. As the automotive industry continues to evolve, these advancements will drive us towards greener, more efficient, and powerful vehicles, paving the way for a sustainable future on the roads. By recognizing the significance of engine components and investing in cutting-edge technologies like the "Studs Service Kit," automotive enthusiasts and manufacturers alike can harness the full potential of these advancements, propelling us into a brighter automotive future.

No comments yet